Sustainability in Fibre Testing: How OFDA Supports Circular, Low-Waste Textiles

- Thomas Hegerty

- Jan 2

- 3 min read

Key takeaways

Accurate, rapid fibre data is foundational for circular fashion. It enables sorting, blending and verification across recycled and virgin inputs. Textile Exchange

OFDA2000 and OFDA4000 provide fast, standards-aligned measurements that help reduce rework and off-spec production. OFDA+1

Recognised methods such as IWTO-47, IWTO-62 and ISO 137 support credible quality documentation and sustainability claims. member.iwto.org+2OFDA+2

Recycled streams are variable. Independent guidance shows the value of robust testing for fibre length, nep levels and blend management. uster.com+1

Content list

Why measurement quality matters for circular fashion

Where OFDA supports eco-initiatives

Standards and verification

Practical steps for mills and brands

FAQ

Why measurement quality matters for circular fashion

Circular fashion depends on inputs that are known, consistent and suitable for reuse or recycling. In practice, recycled fibres can arrive with broader diameter distributions, shorter length profiles and higher nep counts than virgin equivalents. These shifts affect yarn strength, evenness and ends-down in spinning leading to lower yield and increased waste if not managed. Objective, high-throughput testing classifies lots, informs blend design and validates whether material is fit-for-purpose before costly processing begins. Sector guidance also stresses substantiating sustainability claims with reliable measurement and third-party standards to maintain trust with buyers and auditors.

Peer and industry reports consistently note that mechanically recycled cotton, for example, tends to present shorter length distributions and a higher nep risk. Without targeted testing and controlled blending, mills face a trade-off between quality and recycled content targets. Rapid, repeatable measurements let teams locate the “sweet spot” where recycled inputs meet performance requirements, avoiding overspinning, unnecessary twist or heavy cleaning that can introduce additional waste.

Where OFDA supports eco-initiatives

Sorting and blending recycled inputs

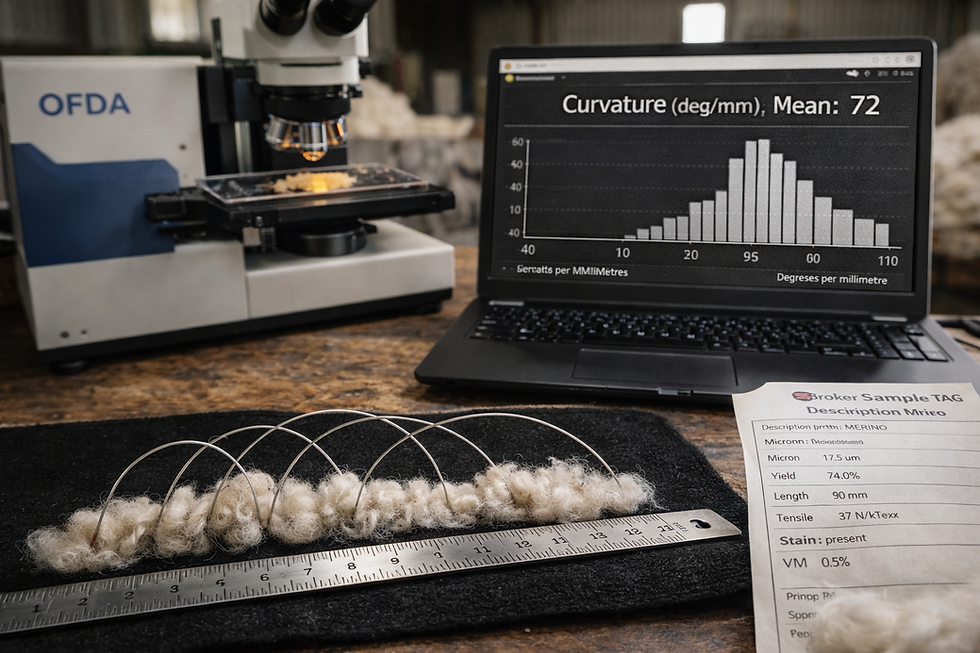

With OFDA, mills can capture diameter distributions quickly and, in tops and slivers, measure true length distributions to triage incoming lots. This enables like-with-like grouping and blending to spec so that recycled and mixed streams reach target spinnability sooner. Consistent inputs reduce variability downstream, from carding through to winding.

Right-first-time processing

OFDA2000 measures up to ~20,000 fibres in about 25 seconds, delivering statistically robust results in near-real time. Teams can use these insights to set carding differentials, drafting parameters and twist levels with fewer trial runs. The upshot is less fibre loss, fewer off-spec bobbins and fewer corrective passes tangible waste reduction in both energy and material.

Transparent claims and reporting

Results aligned with IWTO-47 for wool diameter, and IWTO-62 for length and diameter distributions in tops and slivers, help brands and mills document quality credibly. When recycled content frameworks require evidence of due diligence, standards-aligned OFDA data supports both internal QA and external sustainability disclosures.

Standards and verification

IWTO-47. Measurement of the mean and distribution of wool fibre diameter using an Optical Fibre Diameter Analyser. Referenced across industry quality systems. Woolwise+1

IWTO-62. Determination of fibre length distribution and fibre diameter distribution of wool tops and slivers using OFDA4000. OFDA+1

ISO 137:2015. International method for determining wool fibre diameter using a projection microscope. Complements optical analyser methods in QA programmes. Iteh Standards

Textile Exchange GRS and RCS. Chain-of-custody and recycled-content frameworks that rely on substantiated measurement and documentation. Textile Exchange+1

Practical steps for mills and brands

Map variability hotspots by article and supplier.

Add intake checkpoints for diameter distribution, then re-test after each key blend or processing stage.

Use OFDA4000 on tops and slivers when length distribution and short-fibre content drive spinning stability. OFDA

Track lot-level distributions to refine blend ratios and machine settings.

Reference IWTO and ISO methods in specifications and disclosures to improve traceability. member.iwto.org+1

FAQ

How does OFDA help reduce waste in practice By delivering rapid, high-confidence diameter and length distributions, teams can sort and blend more accurately, set process parameters with fewer trial runs and avoid off-spec batches. OFDA+1

Which standards should I cite when reporting fibre results For wool diameter use IWTO-47. For length and diameter distributions in tops and slivers use IWTO-62. ISO 137 applies to projection microscope measurements. Referencing these improves traceability. member.iwto.org+2OFDA+2

Is there independent guidance for managing recycled fibres Yes. The Textile Exchange’s GRS and RCS frameworks set requirements for recycled material verification and chain of custody. Independent test guidance for mechanically recycled cotton highlights shorter fibre length and higher nep risk, which supports the case for objective fibre analytics. Textile Exchange+2Textile Exchange+2

Can OFDA be used beyond wool

Yes. Depending on processing stage, fibres such as hemp or flax in sliver form can be analysed for length distribution with OFDA4000. OFDA

Comments