How OFDA 2000 delivers rapid in-shed micron — without confusing modes

- Thomas Hegerty

- 2 days ago

- 4 min read

Key takeaways

Greasy staple workflow, typical fibre counts, grease-to-clean correction, throughput: SGS Info Bulletins. SGSCorp+1

FAST/snippet speed and 20,000 fibres: OFDA product page. OFDA

IWTO-47 definition: IWTO listing; Woolwise overview. member.iwto.org +1

Validation vs Laserscan and other devices: Small Ruminant Research (2021). ScienceDirect

Who this article is for

This guide is for wool growers who want fast, objective micron information at shearing or selection — without sending every sample to a lab first. If you need credible numbers to sort mobs, form uniform lines and pick replacements, OFDA 2000 provides on-farm results in minutes using a purpose-built greasy staple workflow, while also supporting clean-snippet testing when required. SGSCorp

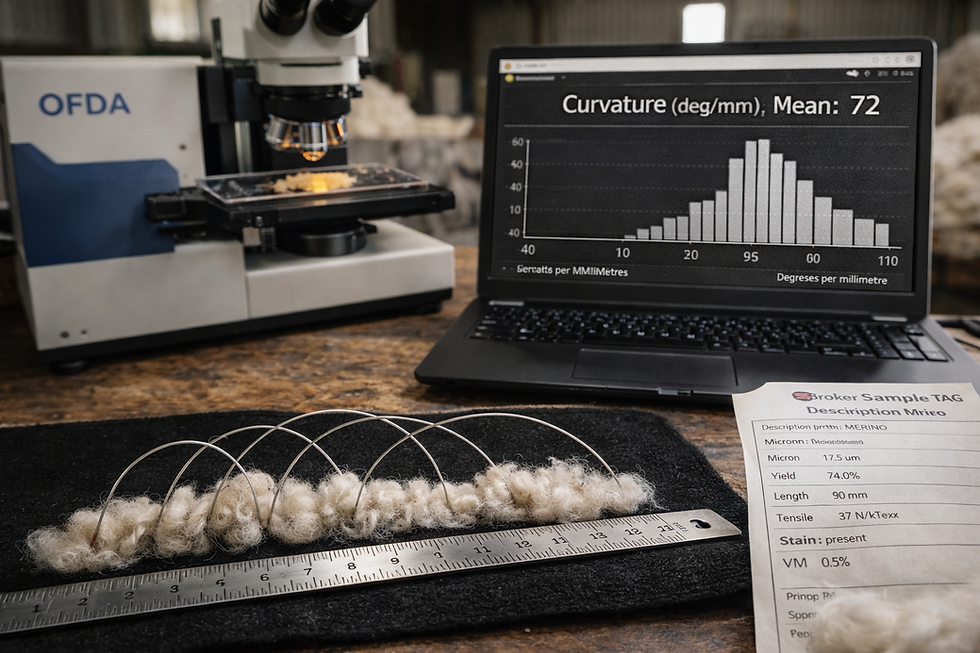

What OFDA 2000 measures

From a small specimen, OFDA 2000 reports mean fibre diameter (MFD), standard deviation, coefficient of variation, a diameter distribution histogram, comfort factor and curvature — the core stats classers use for uniformity and handle. These appear immediately after each run in both modes. SGSCorp +1

Two measurement modes (and when to use each)

1) Fibreglass slide (greasy staple) — the standard in-shed workflow

Place a greasy staple on the fibreglass slide; the instrument measures thousands of fibre segments directly on the staple, applies an internal grease-to-clean correction, and reports clean-equivalent micron and distribution.

Typical fibre counts are about 1,000–3,000 measured segments per staple; trained operators achieve roughly ~100 tests/hour in shed. SGSCorp+1

Use this with mid-side sampling (third last rib, halfway between backline and belly) to keep results representative of the fleece you’ll sell. Icar.org

2) Clean snippet (FAST) — lab-style slide for high counts

Cut ~2 mm clean snippets and spread them on a glass slide. In FAST mode, the instrument traverses the slide and analyses frames in real time, delivering a full diameter distribution for up to ~20,000 fibres in ~25 seconds.

This is the mode aligned with IWTO-47 (Measurement of the mean and distribution of wool fibre diameter using OFDA). OFDA+1

In short: Greasy staple mode is what most growers use in the shed; clean snippet/FAST is for prepared clean fibres and IWTO-47-style slides.

The (separate) 25-second workflow explained — for clean snippets

Speed comes from high-throughput optical image analysis and an automated stage. Thousands of clean fibre images are captured and converted to diameter via a calibration traceable to industry references, returning a distribution in ~25 seconds for up to ~20,000 fibres. Reporting is compatible with IWTO-47 metrics (mean and distribution). OFDA+1

Sampling that keeps results honest (applies to either mode)

Good instrumentation still depends on good sampling. In Australia and New Zealand, the mid-side is the standard objective site. Following recognised protocols reduces bias so your in-shed measurements represent the fleece you’ll ship. icar.org +1

Accuracy and validation against lab methods

Greasy-staple OFDA2000 has long been shown to agree closely with clean staple lab results when recommended procedures are followed, with on-farm precision for micron comparable to a typical fleece-testing lab.SGSCorp

For clean-snippet testing, IWTO-47 defines the OFDA method for measuring mean and distribution of diameter. member.iwto.org+1

Field validations against Sirolan Laserscan (lab reference) report that OFDA2000 predicts MFD with no significant difference from Laserscan and higher accuracy than a lower-cost competitor in the same trial. ScienceDirect

Where it fits against other field devices

Field devices such as FibreLux and FLEECESCAN are used by some growers. The literature indicates OFDA2000 generally tracks more closely to Laserscan in validation work, though all systems benefit from disciplined preparation and calibration. Also note there is no single universal in-shed procedure, so consistent site selection, handling and slide preparation matter whichever device you use.ScienceDirect

Practical tips for wool growers

Sample true mid-side on every animal you wish to rank or sort, and label carefully for traceability. icar.org

For greasy-staple runs: tease micro-staples, align tips and keep VM to a minimum — cleanliness and consistent prep improve detection and repeatability. SGSCorp

Reduce operator variation: use the same preparation steps and (where possible) the same operator within a mob. SGSCorpb

Record MFD, SD, CV and comfort factor for each test so classing decisions remain data-driven and comparable across seasons. (Aligns with common industry advice.) Faculty of Science

Certification: retain laboratory testing via IWTO methods when results are required for contracts or sale. member.iwto.org

Summary

OFDA 2000 supports two complementary workflows. In shed, the fibreglass slide greasy-staple mode measures ~1,000–3,000 fibre segments per staple and converts to clean-equivalent micron, enabling rapid selection and line building at around ~100 tests/hour with trained operators. For clean snippets, FAST mode can analyse up to ~20,000 fibres in ~25 seconds and aligns with IWTO-47 reporting. Independent studies show strong agreement with laboratory routes, including Laserscan validation, so you can make confident in-shed decisions while reserving formal certification for accredited labs. ScienceDirect+3SGSCorp+3SGSCorp+3

FAQ

Which mode should I use in the shed?

Use fibreglass slide (greasy staple) mode — it’s designed for on-farm testing and applies an internal grease-to-clean correction to report clean-equivalent diameter. SGSCorp

How many fibres are measured in greasy-staple mode?

Typically ~1,000–3,000 measured fibre segments per staple (not 20,000). Throughput with a trained operator is about 100 tests/hour. SGSCorp +1

What’s the “25-second” claim about?

That’s FAST clean-snippet mode: up to ~20,000 fibres in ~25 seconds on a clean glass slide; it’s the mode aligned with IWTO-47. OFDA +1

Where should I sample for objective on-farm testing?

Mid-side — centred on the third last rib, halfway between the backline and the belly. icar.org

How close is OFDA 2000 to Laserscan? A 2021 validation against Sirolan Laserscan reported no significant difference in mean fibre diameter for OFDA2000 and better accuracy than a lower-cost competitor in the same trial. ScienceDirect

Comments