From Field to Fabric: Why Flax Fibre Analysis Matters

- design6507

- Aug 7, 2025

- 3 min read

Updated: Sep 24, 2025

In the vast world of natural fibres, few have stood the test of time like flax material. Ancient civilisations spun it into linen for royalty, and today, it’s having a quiet resurgence in fashion, interior design, and sustainable textiles. But beyond its timeless appeal lies a deeper story, one that begins at the microscopic level. Understanding the fibres that make up flax material isn’t just for scientists; it’s essential for designers, manufacturers, and sustainability experts alike.

In this blog, we take a closer look at the flax plant, how its fibres become fabric, and why accurate fibre analysis is crucial for unlocking the full potential of this incredible material.

What is Flax Material?

Flax material originates from the flax plant (Linum usitatissimum), a crop that’s as functional as it is eco-friendly. When processed, its inner stalks yield fibres that are spun into linen, a fabric renowned for being breathable, durable, and beautifully textured.

But flax material is more than just linen. Depending on how the fibres are processed, it can be used in:

Woven textiles for fashion and furnishings

Composite materials for automotive and aerospace industries

Biodegradable packaging and homewares

Technical textiles for industrial applications

Its versatility makes flax an attractive material in a world increasingly focused on reducing plastic use and cutting carbon emissions.

The Journey of Flax: From Fibre to Fabric

To appreciate flax material, it helps to understand its journey:

Cultivation: Flax grows best in cool climates with well-drained soil. Within 100 days of planting, it matures and is ready for harvesting.

Retting: This is a natural process that breaks down the pectin that binds fibres to the woody core of the stalk. It can be done through dew, water, or enzyme-based methods.

Breaking and Scutching: These processes remove the woody parts of the stalk, leaving long flax fibres behind.

Hackling: The fibres are combed to separate the long “line” fibres (used for fine linen) from shorter “tow” fibres (used in coarse textiles or composites).

Spinning and Weaving: Finally, the fibres are spun into yarns and woven into fabric.

Throughout this journey, the quality of the raw flax fibre directly influences the characteristics of the final material, whether it's soft and delicate or strong and rugged.

Why Fibre Analysis Matters for Flax Material

The natural world is wonderfully unpredictable and flax is no exception. Depending on growing conditions, harvesting methods, and processing techniques, the fibre characteristics can vary significantly. This is where fibre analysis becomes a game-changer.

Fibre analysis helps identify:

Fibre diameter and length

Fineness and uniformity

Crimp, curvature, and alignment

Variability between batches or regions

For manufacturers working with flax material, this data is critical. It informs decisions about how to process the fibre, predict fabric performance, and ensure consistency in quality across different production runs. In an industry where even minor inconsistencies can lead to major production issues, fibre analysis bridges the gap between raw material and reliable outcomes.

Sustainability and Traceability in Flax Material

One of the standout features of flax is its low environmental impact. It requires less water than cotton, grows without heavy chemical inputs, and can be grown in rotation to support soil health. But sustainability doesn’t stop at the farm.

Traceability is becoming essential in textile supply chains. Brands want to verify not only where their fibres come from, but how they perform. By integrating fibre analysis into production, companies can ensure their flax material meets both environmental and performance benchmarks.

Consumers today are more informed and curious. They want to know that their breathable linen shirt or eco-friendly table runner came from responsibly sourced flax that delivers both comfort and durability.

Ready to Get the Most Out of Your Flax Fibre?

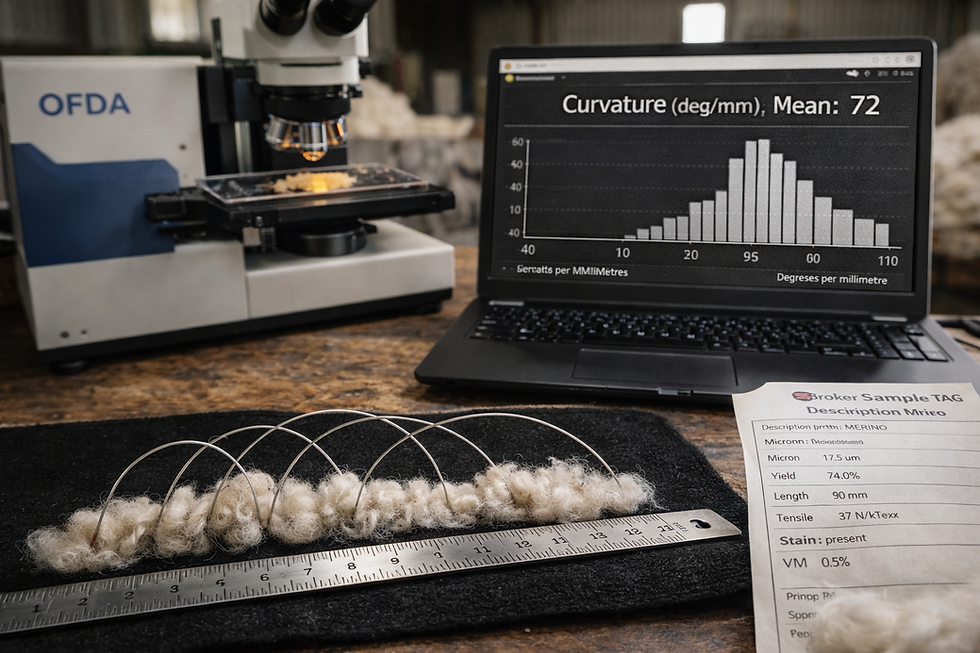

At Robotic Vision, we support fibre industries with precision fibre analysis tools like the Optical-based Fibre Diameter Analyser (OFDA) , an image-based system that offers detailed, reliable insights into natural fibres like flax. Its precision allows for deeper fibre understanding and better decision-making.

Discover how our fibre testing technology can help you improve your flax material quality, traceability, and innovation.

Comments