Measuring flax (linen) fibre fineness and length: a practical OFDA workflow

- Thomas Hegerty

- Nov 3, 2025

- 4 min read

Flax (linen) is prized for strength, handle and sustainability. What’s harder is getting consistent, comparable measurements of fineness and length. Unlike wool, flax doesn’t have a single, trade-wide true-length standard; instead, labs mix permeametric fineness (airflow) and image-analysis width methods, plus microscopy for identification. (Iteh Standards)

This guide sets out what’s standard today, what’s evolving, and a practical OFDA-based workflow you can apply now—clearly labelled where we’re adapting wool methods to bast fibres.

Why fineness and length matter

Fineness/width affects yarn count, handle and specific strength; standards address flax fineness via permeametric approaches (airflow resistance) or image-analysis widths. (Iteh Standards)

Length distribution and short-fibre content influence spinning performance and evenness; methods to characterise flax length are varied (e.g., optical/image analysis, adaptations of fibre-quality analysers), and harmonisation is still developing. (MDPI)

Today’s testing landscape (what’s actually used)

Flax fineness — ISO 2370 (permeametric): Defines three airflow-based routes to determine fineness of flax fibres (constant flow with parallel fibres; simplified constant flow; constant pressure), using resistance of a compressed plug of fibres. It’s applicable to a range of flax forms. (Iteh Standards)

Flax width — ASTM D7879: Image-analysis method to measure average and distribution of flax fibre widths from 2D projections—useful when you need a histogram, not just a mean. (Antpedia)

Fibre identification — ISO 20706-1: Microscopy procedures for bast fibre identification (flax, hemp, ramie) and blends—important when validating raw material streams. (Iteh Standards)

Research & tools: Labs explore optical/automated systems for natural fibres, including flax (e.g., Fibre Quality Analyzer studies on length/counts in multiple fibres). (MDPI)

Takeaway: For flax you’ll often combine ISO 2370 fineness (airflow) with ASTM D7879 width distributions (image analysis) and ISO 20706-1 for identification—then tailor length analysis to your process.

Where OFDA fits (and what’s proven)

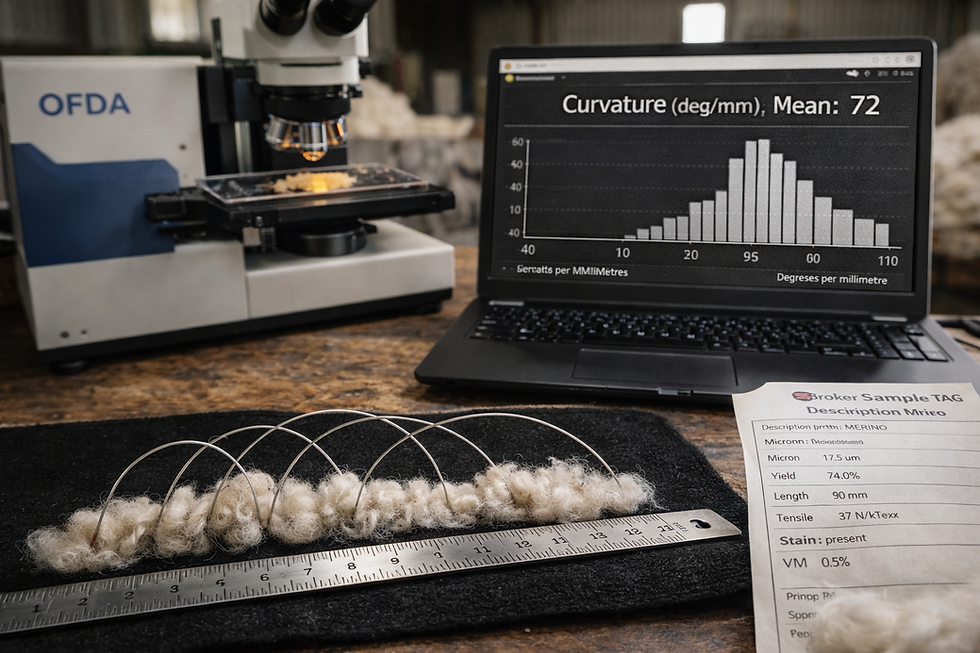

OFDA 2000 (portable/bench) captures large-count width distributions from optical images—ideal when you need distribution-aware, repeatable measurements beyond a single average. Robotic Vision’s product materials and training show high-throughput optical measurement and histogram outputs. (OFDA)

OFDA 4000 (automated sliver/top) measures true length distribution and diameter for wool slivers/tops under IWTO-62. While IWTO-62 is a wool standard, its optical, distribution-first approach is directly relevant to bast-fibre QA when you present it clearly as an adapted workflow for flax slivers/rovings. (OFDA)

(We’re explicit: OFDA 4000’s true-length method is standardised for wool; applying the same optical distribution principles to flax is an adaptation.)

A practical OFDA workflow for flax/linen (step-by-step)

Define the decision Are you targeting yarn count and handle (fineness/width), or controlling breakage and variability (length distribution/short-fibre tail)?

Identify the fibre (when needed) Use ISO 20706-1 microscopy for bast fibre/blend identification before QA workups. (Iteh Standards)

Prepare the sample Gently open and align; avoid creating artefacts. For width: mount fibres for clear 2D imaging. For length: create sliver/tuft preps suitable for optical capture (OFDA 4000 “tuft/sliver” style preps). (OFDA)

Measure fineness/width

Standards route: Run ISO 2370 (permeametric fineness) where airflow rigs are available. (Iteh Standards)

Distribution route (histograms): Use ASTM D7879 style image analysis, or OFDA 2000 to produce width distributions with large counts; clearly label results as width (proxy for fineness). (Antpedia)

Measure length distribution (if applicable) Use OFDA 4000 to obtain true length distribution on sliver/rovings, explicitly documenting that this is a bast-fibre adaptation of a wool sliver method (IWTO-62). Report percentiles and a short-fibre metric matched to your spinning line. (OFDA)

Report transparently Publish histograms (width and, where measured, length), plus mean, SD, CV. State method + instrument, and whether values are airflow fineness (ISO 2370) or width (ASTM D7879/optical). (Iteh Standards)

Reading the results (what to watch)

Width distribution: A long coarse tail can cap achievable yarn counts or affect hand. Width distributions from image/optical methods make tail risk visible. (Antpedia)

True length distribution: Percentiles (P10/P50/P90) and short-fibre% help diagnose carding/combing settings; analogous optical approaches are used in other fibres to understand breakage and variability. (MDPI)

Limitations & transparency (to build trust)

Different measures ≠ interchangeable: Permeametric fineness (ISO 2370) and width (ASTM D7879/optical) are not the same metric. Label clearly and don’t mix thresholds. (Iteh Standards)

Method declarations: Always name the standard and instrument (e.g., “OFDA 2000 width distribution”, “OFDA 4000 length distribution—adapted from IWTO-62”). (OFDA)

Why choose OFDA for flax (fact-based, pragmatic)

Distribution-first data: OFDA 2000/4000 produce histograms with large counts, enabling more reliable settings and supplier specs than a single mean. (OFDA)

Field to lab: OFDA 2000 suits development and mill labs needing quick width distributions; OFDA 4000 scales measurement on slivers/rovings and supports process control with true length distribution (clearly marked as an adapted bast-fibre workflow). (OFDA)

Global support: Australia-based, serving mills, labs and producers worldwide with training and documentation. (OFDA)

FAQs

Is there a single “micron” standard for flax like wool? No. Flax fineness is addressed by ISO 2370 (airflow/permeametric), and ASTM D7879 covers image-analysis widths; they are different measures and should be reported as such. (Iteh Standards)

Can OFDA measure flax fineness? Yes—as width via optical image analysis with OFDA 2000. Report it explicitly as width (proxy for fineness) and include the distribution. (OFDA)

How do I measure flax length distribution? You can use OFDA 4000 to measure true length distribution on slivers/rovings; document that this is an adaptation of a wool sliver method (IWTO-62) for transparency. (OFDA)

References (selection)

Flax fineness standard (airflow): ISO 2370:2019 — Permeametric methods for determination of fineness of flax fibres (preview). (Iteh Standards)

Flax width distribution (image analysis): ASTM D7879 — Determining Flax Fiber Widths Using Image Analysis (distribution + average). (Antpedia)

Bast identification: ISO 20706-1:2019 — Bast fibres identification via microscopy. (Iteh Standards)

Length/counts (context): Study exploring FQA for cotton, flax, ramie, hemp, etc. (length/count methodology development). (MDPI)

OFDA product context: OFDA2000 (high-throughput optical width/diameter distributions); OFDA4000 (automated sliver measurement incl. tuft/sliver modes). (OFDA)

Company & support: Robotic Vision (OFDA) — Australia-based, global clients. (OFDA)

Comments