IWTO Compliance: Why Accurate Fibre Testing Matters

- design6507

- Nov 28, 2025

- 7 min read

TL;DR (Summary Box)

• The International Wool Textile Organisation (IWTO) sets global standards for sampling, testing and reporting (IWTO Wool Testing).

• Accurate, repeatable fibre testing underpins fair pricing, trade credibility and fleece data integrity.

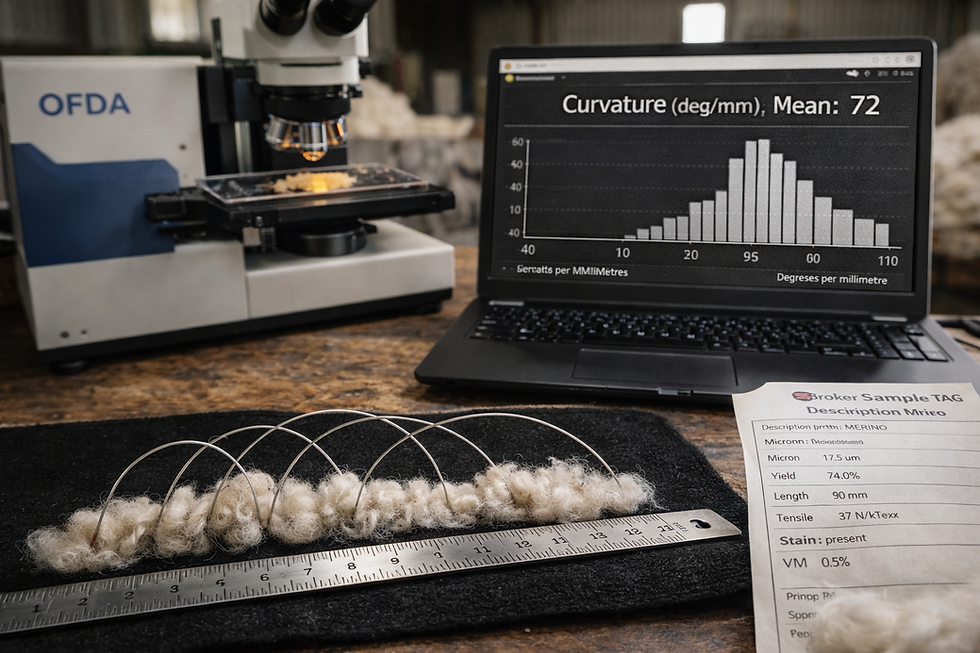

• OFDA (Optical Fibre Diameter Analyser) enables objective fibre measurement (OFM) with high throughput and IWTO‑aligned workflows (overview in SGS OFDA technical note).

• Labs and producers strengthen compliance via calibration routines, proficiency testing and robust audit trails (see Interwoollabs).

• Use IWTO‑recognised methods (e.g., IWTO‑47 for OFDA; IWTO‑12 for Laserscan) and document QA to maintain buyer confidence (methods listed in IWTO Wool Testing Resources).

Wool moves across borders on trust. That trust is built on standardised, objective measurement especially fibre diameter, length and strength validated by the International Wool Textile Organisation (IWTO). IWTO compliance supports fair pricing, transparent documentation and confidence from farm to fabric. This post explains what IWTO is, why compliance matters, and how OFDA supports accurate, repeatable results aligned to global wool industry standards.

Explore how precision in fibre testing ensures industry trust and global competitiveness.

Table of contents

What is IWTO and why is compliance important?

The critical role of fibre testing in the wool industry

What is OFDA and how does it work?

Benefits of OFDA for IWTO‑aligned testing

IWTO‑recognised fibre testing methods and standards

Quick reference: methods table

Why accuracy and repeatability in fibre testing matter

Trust and transparency in global wool trade

How OFDA supports IWTO compliance for labs and producers

Workflow: from sampling to certificate

Ensuring ongoing compliance and innovation

Glossary

Case study teaser

FAQs

Key takeaways

References

What is IWTO and why is compliance important?

The International Wool Textile Organisation (IWTO) is the global body that publishes test methods and regulations for wool (see the Wool Testing overview and the Wool Testing Resources page). Its standards provide a common language for sampling, testing and reporting. Compliance matters because it: - Improves market access many buyers require an IWTO test certificate (noted in IWTO Wool Notes 2024).- Supports transparency and fairness standardised methods reduce disputes.- Maintains global trade integrity data is comparable across recognised wool testing laboratories.

CTA: Ensure your testing meets IWTO standards get in touch today.

The critical role of fibre testing in the wool industry

Fibre diameter (micron), length and strength influence processing performance, yarn behaviour and value. Mean fibre diameter is repeatedly shown to be a major pricing variable (e.g., Animal Production Science; Woolwise Fibre Diameter). Inconsistent testing erodes confidence, creates rework and can trigger claims. That’s why objective fibre measurement (OFM) using validated instruments and methods is essential.

What is OFDA and how does it work?

OFDA (Optical Fibre Diameter Analyser) is an optical imaging system that rapidly measures thousands of fibres to calculate mean and distribution of diameter and, on certain models, length and curvature. See the neutral explainer from SGS: OFDA technical note.

Benefits of OFDA for IWTO‑aligned testing

Real-time feedback for producers and classers to guide shearing and clip preparation (see OFDA2000).

High-throughput lab testing for efficient, scalable operations (see OFDA4000).

Compatibility with IWTO test protocols applied by licensed labs (see IWTO Wool Testing and Wool Testing Resources).

CTA: Explore OFDA options for precision and compliance.

IWTO‑recognised fibre testing methods and standards

IWTO publishes formal test methods (often referred to as the Red Book). See: IWTO Wool Testing Resources and the older Index of Specifications (PDF): 2017 Index.

For fibre diameter, commonly referenced specifications include: - IWTO‑47 Optical Fibre Diameter Analyser (OFDA) for diameter distribution (IWTO‑47 page; background comparison in SGS bulletin). - IWTO‑12 Laserscan for diameter distribution (IWTO‑12 page; see also AWTA overview). - IWTO‑28 Airflow methods for certain sample forms (SGS comparison bulletin). - IWTO‑08 Projection Microscope (historical reference/benchmark applications) (see same SGS comparison).

Proficiency & certificationInter‑laboratory ring testing and formal accreditation (e.g., ISO/IEC 17025) help verify bias and precision, demonstrating a lab’s ability to produce comparable results. See Interwoollabs association and membership/IH Tops. ISO/IEC 17025 overview: ISO website.

Quick reference: methods table

Method code | Instrument / approach | Measures (typical) | Sample forms (typical) | Typical use |

IWTO‑47 | OFDA (optical imaging) | Mean, distribution; additional metrics by model | Core, staples, sliver/tops (per method scope) | Routine lab testing; on‑farm guidance (where applicable) |

IWTO‑12 | Laserscan (laser scattering) | Mean, distribution | Core, sliver/tops | Routine lab testing |

IWTO‑28 | Airflow (indirect) | Mean (inferred) | Sliver/core (method‑specific) | Legacy/selected applications |

IWTO‑08 | Projection microscope | Distribution parameters; reference | Selected verification; research/benchmark | Reference/verification work |

Note: Always consult the current IWTO method for scope, apparatus, calibration and reporting requirements (purchase links on the IWTO store).

Why accuracy and repeatability in fibre testing matter

Small shifts in micron classification can move a lot between price bands. For example, a lot measured at 18.4 µm may be sold in a finer bracket than the same lot measured at 19.1 µm. Even if both results are within normal repeatability, the commercial impact can be material. Robust sampling, validated methods and traceable calibration protect value (evidence that MFD drives price: Animal Production Science; Woolwise notes).

Trust and transparency in global wool trade

Consistency builds credibility with mills and brands that specify tight micron windows.

Inaccurate data undermines supply chains, from mis‑specified tops to spinning performance issues.

IWTO certification and proficiency testing signal strong QA and fleece data integrity (see IWTO Wool Testing and Interwoollabs).

CTA: Contact our team for compliant fibre testing solutions.

How OFDA supports IWTO compliance for labs and producers

For laboratories- Method alignment with IWTO‑recognised procedures (e.g., IWTO‑47, IWTO‑12).- Calibration discipline using appropriate standards sets and documented schedules (Interwoollabs IH Tops; SGS OFDA note).- Proficiency participation to verify bias and precision (Interwoollabs).- Software traceability with audit trails for edits and approvals (quality systems aligned to ISO/IEC 17025).

For producers and classers- On‑farm OFDA testing provides rapid, objective results that align with commercial practices (see OFDA2000).- Real‑time decisions improve lot building and reduce reclassing before sale.

Workflow: from sampling to certificate

Representative sampling (per IWTO guidance).

Instrument checks & calibration (daily checks + scheduled calibrations).

Objective testing (OFDA, Laserscan, etc. per method scope).

Quality review (controls, bias/precision monitoring).

Reporting & certification (licensed lab issues results).

Traceability & audit (retain records, ring‑test performance, corrective actions).

Ensuring ongoing compliance and innovation

IWTO methods and regulations evolve; see IWTO Wool Notes 2024 for current context and reminders to consult the Red Book. Staying current with method updates, maintaining training, and validating workflow changes are essential. Platforms like OFDA continue to improve throughput, automation and software controls while maintaining alignment with industry standards.

Glossary

Objective fibre measurement (OFM): Testing that relies on validated instruments and methods to minimise operator bias.

IH Tops / reference materials: Recognised standards used for calibration and bias control (see Interwoollabs memberships).

Inter‑laboratory (ring) testing: Comparative trials across multiple labs to verify precision and bias (see Interwoollabs association).

ISO/IEC 17025: International standard for testing laboratory competence (see ISO).

Fleece data integrity: The quality and traceability of data describing a fleece, lot or clip.

FAQs

What does “IWTO compliance” actually mean?IWTO compliance means sampling, testing and reporting are performed according to formal IWTO methods and regulations (see IWTO Wool Testing and Wool Testing Resources). Results are comparable across recognised labs and suitable for trade documentation.

Which IWTO methods are most relevant to fibre diameter?Commonly referenced methods include IWTO‑47 (OFDA), IWTO‑12 (Laserscan), IWTO‑28 (Airflow) and IWTO‑08 (Projection Microscope). Method details and purchase: IWTO Wool Testing Resources. Context and comparisons: SGS bulletin.

Is OFDA recognised under IWTO standards?Yes. OFDA measurements for fibre diameter distribution are covered under IWTO‑recognised procedures (see IWTO‑47 on the IWTO store). Licensed labs integrate OFDA within ISO/IEC 17025 quality systems.

How does OFDA testing support accuracy and repeatability?OFDA measures thousands of fibres via automated image analysis, reducing operator bias. Accuracy is maintained through routine calibration with recognised standards and ongoing proficiency testing (see SGS OFDA note; Interwoollabs).

What’s the difference between OFDA and Laserscan?Both deliver objective fibre diameter data using different measurement principles (optical imaging vs laser scattering). Choice depends on workflow, sample form and accreditation scope (see IWTO‑12 on the IWTO store and AWTA laserscan context).

How often should instruments be calibrated?Daily checks (or per shift) are common in high‑throughput labs, alongside scheduled calibrations per the quality manual and manufacturer guidance (see Interwoollabs IH Tops).

Do on‑farm OFDA tests align with commercial lab results?They can, provided sampling is representative and the device is maintained and calibrated. On‑farm testing provides guidance, while sale certificates typically come from licensed laboratories (see OFDA2000 and IWTO Wool Testing).

What documentation should a lab keep for audits?Calibration records, method SOPs, training logs, ring‑test participation, corrective actions and software audit trails (see ISO/IEC 17025 overview: ISO).

How do IWTO standards evolve and how do we keep up?IWTO issues periodic updates (see Wool Notes 2024 and Wool Testing Resources). Monitor notices, review Red Book changes, train staff and validate any workflow updates before releasing results.

Key takeaways

Accuracy and repeatability protect value: small micron differences can move a lot between price bands.

IWTO alignment is essential: use trusted fibre test methods (e.g., IWTO‑47 for OFDA, IWTO‑12 for Laserscan).

OFDA is a proven, high‑throughput choice for objective, IWTO‑aligned measurement in labs and on‑farm contexts (see OFDA4000 and OFDA2000).

Strong calibration and proficiency testing underpin credible certificates and fleece data integrity (see Interwoollabs).

References

IWTO Wool Testing overview: https://iwto.org/wool-supply-chain/wool-testing/

IWTO Wool Testing Resources (Red Book): https://iwto.org/resources/wool-testing-resources/

IWTO Index of Specifications (PDF): https://cdn.ymaws.com/www.member.iwto.org/resource/resmgr/publications/index-_red_book_2017.pdf

IWTO‑47 method page: https://www.member.iwto.org/store/viewproduct.aspx?id=12408363

IWTO‑12 method page: https://www.member.iwto.org/store/viewproduct.aspx?id=12408762

SGS OFDA technical note: https://www.sgs.com/en/-/media/sgscorp/documents/corporate/technical-documents/wool-testing-info-bulletins/SGSAGRI_OFDA_32dA4EN1403.cdn.en.pdf

SGS Airflow vs OFDA vs Laserscan comparison: https://www.sgs.com/en/-/media/sgscorp/documents/corporate/technical-documents/wool-testing-info-bulletins/SGSAGRI_Airflow-OFDA-Lasercan_33bA4EN1403.cdn.en.pdf

Interwoollabs Association (ring trials): https://www.interwoollabs.org/association/

Interwoollabs Memberships / IH Tops: https://www.interwoollabs.org/memberships/

AWTA Laserscan/ATLAS overview: https://www.awtawooltesting.com.au/index.php/en/services/equipment-manufacture/raw-wool-laboratory-equipment

Animal Production Science Pricing determinants: https://www.publish.csiro.au/an/an14744

Woolwise Fibre diameter & pricing notes: https://www.woolwise.com/wp-content/uploads/2017/07/Wool-472-572-08-T-09.pdf

IWTO Wool Notes 2024: https://iwto.org/wp-content/uploads/2024/06/IWTO-Wool-Notes-2024.pdf

Comments